During Summer 2023, I interned at Second Order Effects, an engineering consulting company in El Segundo, CA. As a member of the mechanical engineering team, I was assigned to a client who required a structural and electrical redesign of a handheld medical device. I was tasked with increasing the device’s battery removal ease of use to comply with regional battery disposal regulations. My role on the project included current design intake, criteria writing, component design, and prototyping deliverable hardware. The project began with intake of the original design, familiarizing myself with the device use cases and operating procedure. The device enclosure was a clamshell injection molded from ABS. It used four screws threaded into extruded bosses for retention which must be removed for battery removal. I familiarized myself with the PCB assembly and integration with the battery compartment, trigger, and power switch. With a full understanding of the current design, I communicated with the customer to develop a list of desired functions and constraints that represented their needs.

I then worked with the electrical engineering team to write design criteria for mechanical changes and to ensure proper integration with the electronic redesign. The enclosure needed to add battery removal functionality while maintaining electrical switch functionality and device ergonomics.

Once the requirements were set, I began researching removable battery technology. I created sketches of candidate solutions and completed trade studies to down-select the optimal solution. I defended the choice to my supervisor and began designing the first prototype, a battery cap and c-snap mechanism.

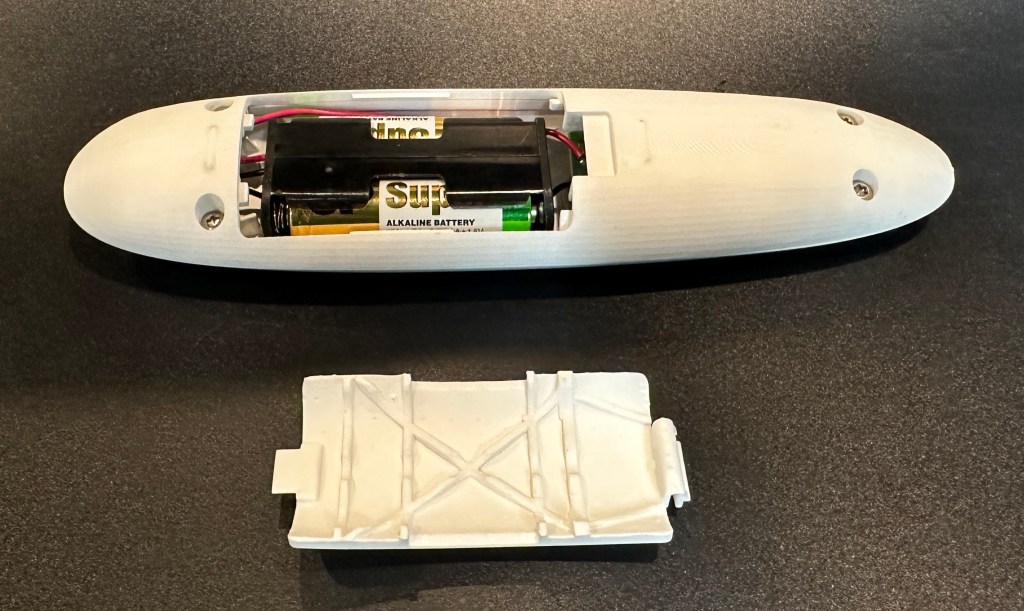

I began by using a force gauge to test existing c-snap battery caps to find the optimal release force. Then, I modified the existing device enclosure CAD files to incorporate the mechanism with no changes to the device ergonomics. The feel of the device was paramount – investors received demo devices and would use its in-hand feel as a quick litmus test for device quality. The mechanism was designed so that release force could easily be adjusted. Through iterative SLA printing in an ABS-like material, I created prototypes to present to the client and confirm integration with internal electronics.

When presenting the design choice and prototype to the client, they said “this is exactly what I wanted”. The success of the design presentation led to the client pursuing additional mechanical design contracts with the company.

With the client’s approval of the design, I completed the CAD design, adding modifying features with intent for injection molding. I am grateful I was given ownership of the mechanical system and could provide meaningful changes for the client.