Project overview

I am the liquid propulsion team lead for Duke AERO, the university’s high power rocketry club. Team goals are set high: design, develop, and test AERO’s first liquid bipropellant rocket engine during the 2023-24 academic year. The system is dubbed Eno, named after a river near Duke’s campus. The engine is pressure fed using a nitrous oxide/kerosene propellant mix targeting 5 kN of thrust. As lead of the project, it is my responsibility to facilitate communication between subsystem designers and ensure system architecture choices relate back to our design criteria. And in some cases, update or delete criteria that are unnecessary or do not match our goals. Additionally, own the design and analysis of the thrust chamber and injector.

Engine Sizing

Eno is not designed for a specific mission but instead to serve as a learning vessel for the basics of rocket propulsion. The engine is regeneratively cooled with a target burn time of 10 seconds, targeting a thrust of 5 kN. Eno’s testing campaign will focus on giving the team practical experience in propellant handling, ground system equipment testing, and validating injector and thrust chamber design choices.

Nitrous oxide and kerosene were chosen as propellants due to their accessibility and long history in rocket engines. The system is pressure fed with nitrogen to reduce complexity compared to pump fed systems. Nos is a popular oxidizer in amateur hybrid rocket engines due to its self pressurization. Kerosene is relatively safe to handle and purchase and will provide a sufficient specific impulse in combination with nos. Kerosene’s soot production provides a thermal barrier between the combustion gasses and chamber wall which reduces the demand on the regenerative cooling.

Chamber pressure and exit pressure were chosen as 350 psi and 8.3 psi (pressure at 17k ft), respectively and an O/F ratio of 4. Rocket Propulsion Analysis (RPA) was used to conduct a chemical equilibrium analysis of the combustion reaction, predicting a chamber temperature of 2400 K. To size the nozzle, isentropic flow was assumed and stagnation equations were used to determine flow properties along the length of the nozzle. The hand-calc sizing compared well to sizing from RPA. The diverging nozzle section is conical with a half angle of 15 deg. An l* value of 35 in was chosen to allow for complete combustion before the nozzle throat. The inner diameter of the combustion chamber is set at 3.75 in for compatibility with common o-ring sizes for injector sealing.

Thrust Chamber Design and Analysis

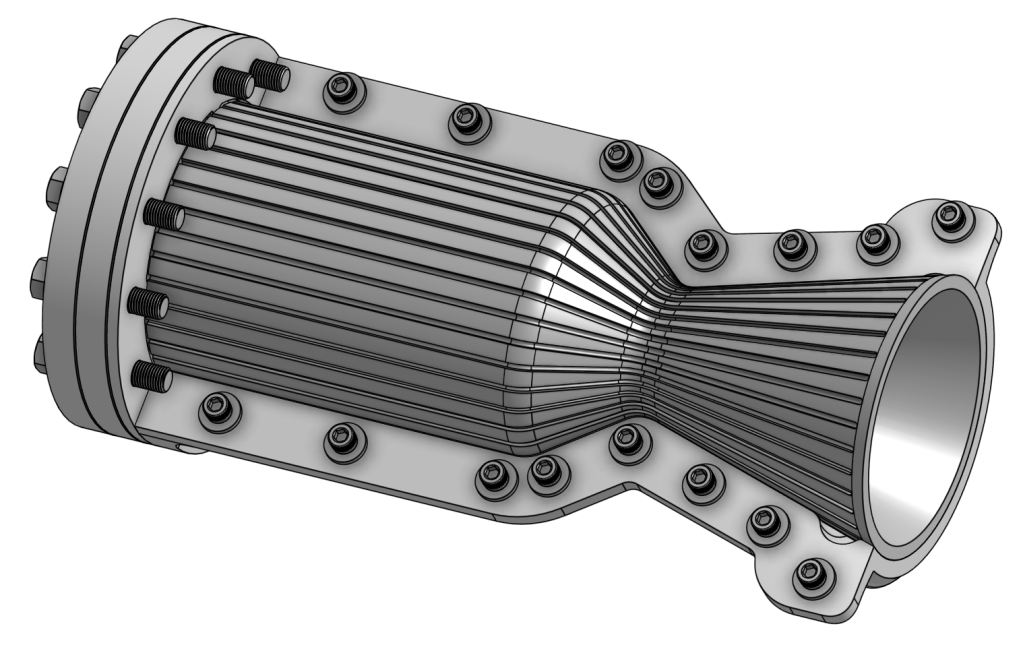

The thrust chamber consists of an inner liner and outer clamshell jacket. The thin liner follows the inner contour of the chamber and has small channels milled into it for coolant. The jacket is bolted around the liner to enclose the coolant channels. The liner is made of stainless steel for its strength at high temperatures while the jacket is milled from aluminum to reduce weight and cost. Kerosene is plumed into an annulus in the jacket at the exit of the nozzle where it is distributed into each cooling channel. Gasket maker is used to seal the transition between the lip on the liner at the nozzle exit and the clamshell flanges.

ANSYS Mechanical is used to create a coupled structural-thermal model of the thrust chamber. To save on computing costs, the chamber is analyzed as a 2D cross section perpendicular to the length of the chamber. Boundary conditions for the setup include internal pressure, hot gas convection, coolant fluid pressure and coolant convection. Hot gas convective heat transfer coefficients are determined with the Bartz equation and pressure is found by applying the mach area relation to the pressure stagnation equation. Cooling convective heat transfer coefficients are found with the Sieder-Tate Nusselt number correlation because it corrects for high temperature differences between channel wall temperature and bulk coolant temperature. Coolant pressure is estimated at 100 psi above chamber pressure.

Iterative analysis shows that the optimal number of cooling channels is around 36. Any more would add machining time with little payoff and less would result in too high of liner temperatures.

Cross sections are analyzed at the nozzle exit, throat, entrance, combustion chamber, and between these points. The total heat flux into the coolant for two adjacent sections is used to interpolate the heat flux at any section between these two. Then the total temperature rise of the coolant between two sections may be calculated. Vaporization is not a concern as kerosene is above its critical pressure. The kerosene temperature is expected to rise from 300 K at the entrance to just over 400 K at the injector inlet.

Injector Design

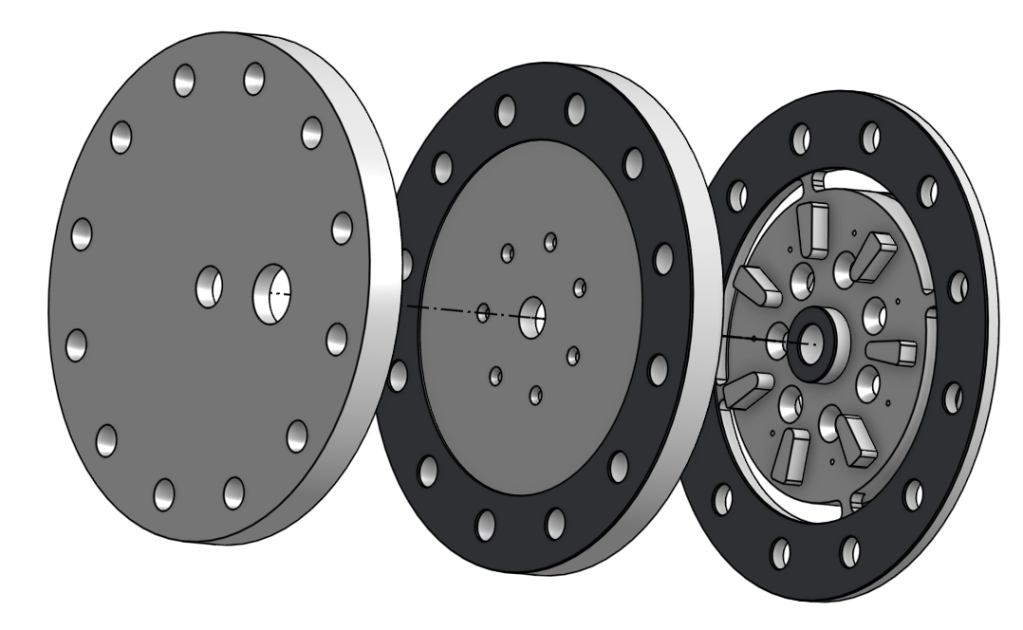

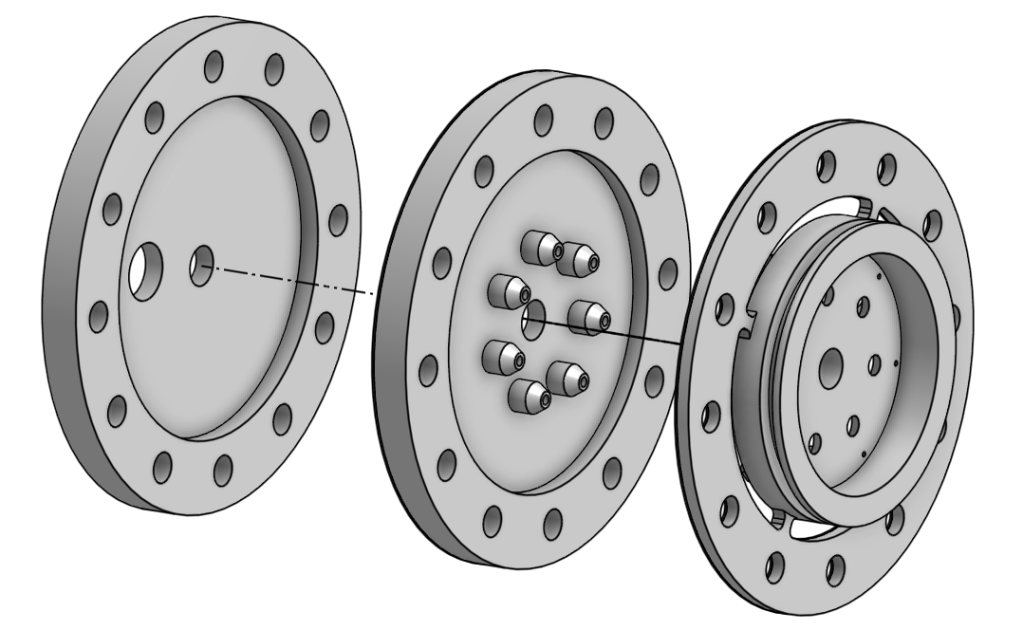

Eno will use a novel injector designed for rapid manufacturing with simple machining operations while exceeding the efficiency of other simple injectors such as the shower head.

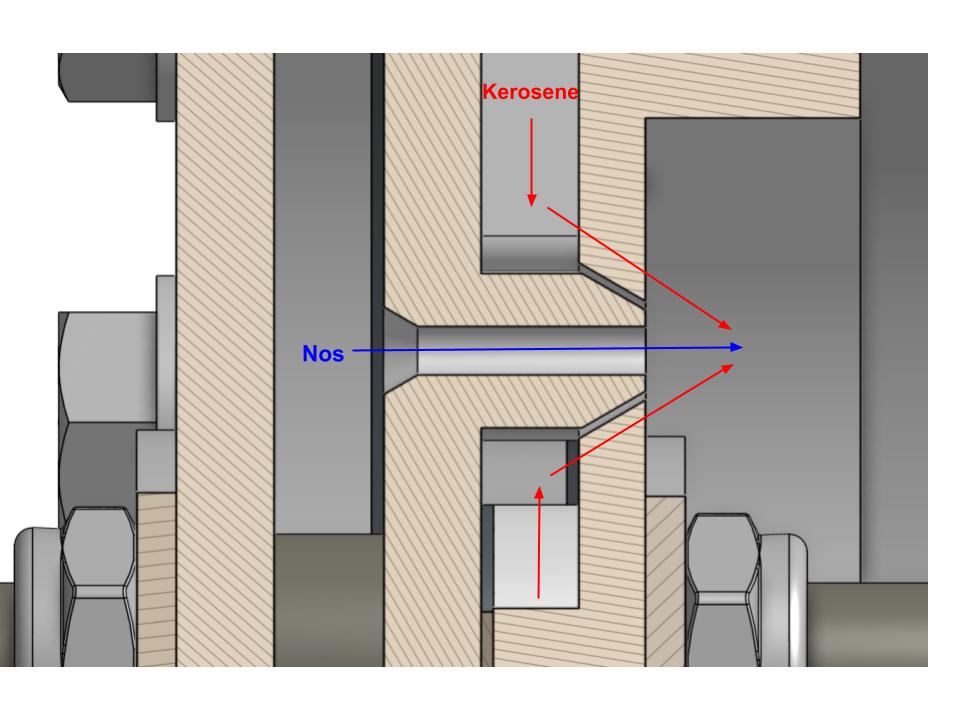

The “cone injector” for Eno consists of a countersunk hole and matching chamfered standoff. Kerosene is sped up through the gap between the hole and the standoff, where it exits at a 45 deg angle to the injector face (similar to the outer streams in an unlike triplet).

Nitrous oxide is plumed through a through hole in the standoff to collide and atomize with the kerosene. The injector elements are made of stainless steel to expand at the same rate as each other and the liner. Stainless steel tubing is run through the enter of the injector for chamber pressure readings. Flanges between plates are sealed with high temperature graphite gaskets.

Stay tuned here for more updates as the team begins manufacturing!