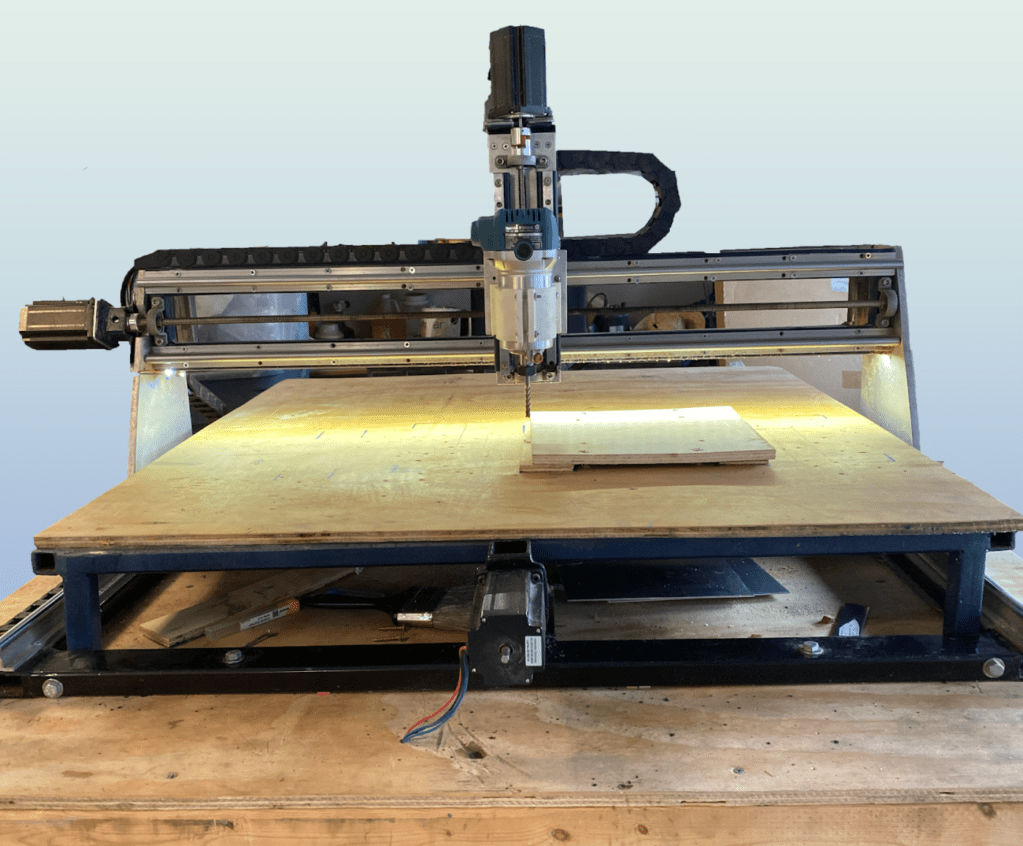

I built the CNC router to expand my home shop capabilities. I wanted a machine with a 3×3 ft bed size, the rigidity and power to cut through aluminum, the ability to maintain precision during long jobs, and cost much less than other machines on the market. I designed the frame so it could be welded from 1×1 in square steel tubing, which is cheap and readily available. Each axis is directly driven by a stepper motor turning an acme lead screw which is connected to the frame by a t-nut, saving costs compared to other drive systems while still maintaining acceptable precision. GRBL software runs on an Arduino in conjunction with stepper motor drivers to send commands and power to the motors. A handheld wood router mounted on the z-axis acts as a light, cheap, and reliable machine head to cut material. The project cost a fifth of a comparable commercial product while meeting all design requirements. The router can easily and accurately mill wood and aluminum at high speeds. I learned the importance of designing manufacturable products while building the CNC router. I had to design parts that I could build by hand with basic home shop tools and easily accessible raw materials. The result is a machine that is low cost, effective, and easy to manufacture.